Most complex phenomena observed in manufacturing processes are relating to or coupled with other physical or chemical phenomenon such as turbulence diffusion, structure deformation, heat transfer, aeroacoustics, electromagnetic fields or chemical reactions. While the use of computer simulations is rapidly spreading in industry as a helpful engineering tool, its limitations regarding coupled phenomena is now well recognized. This is because each simulation method has been optimized for a specific phenomenon, and once two or more solvers of different phenomena are coupled to deal with a complicated target, computational performance is seriously degraded. Thus our main objective is to establish a new simulation framework for complex and coupled phenomena by utilizing the HPC environment and to expand its use in engineering applications by fostering next-generation digital engineering.

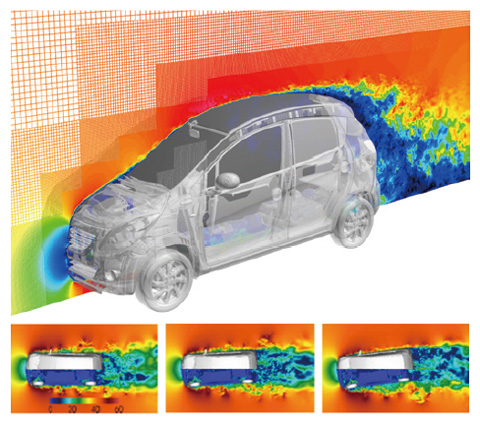

For that purpose, we are researching and developing a unified simulation method called CUBE. Its goal is to solve multiple partial differential equations on the same hierarchically structured grid system. To date, we have singled out three main areas to improve this method. First, to speed up CUBE by considering next-generation hardware architecture and to realize real time simulations for industrial use. Second, to improve the accuracy of CUBE for dealing with coupled phenomena when realizing real world simulations for engineering applications, as this will expand the possibility of using simulations in real operating conditions. Third, to promote the sophisticated use of CUBE in manufacturing processes: For example, applying it to multi-objective optimization by utilizing assimilation of existing experimental data, or by applying deep learning to big data simulations.